Serialization / coding / labelling

Since 09.02.2019, prescription medicines may only be put into circulation in Germany if the packaging has received an individual serial number and the package's intactness can be ascertained. This so-called "serialization" provides reliable counterfeit protection to medicines.

Our top-quality machines ensure maximum availability and reliability for the printing, coding and labelling of packages.

This also includes the secure attachment of various sealing labels.

Our comprehensive expertise in the field of these highly complex processes is our hallmark and guarantees the integrity and perfect condition of the products to our customers and to the end user. We offer modern and reliable solutions which meet the high standards of our customers and the requirements of industrial production in every form and aspect.

Stegemann video

For this purpose, we work together with a qualified service provider who converts your xml files into the xml format required by us and afterwards returns your files back to your database in your own xml format.

For this process it is irrelevant whether the folding boxes provided by you are flat or already filled.

We can also provide labels with serial numbers.

With the new T15 aggregation unit from Mettler-Toledo, Stegemann as a contract packer is now also able to map and offer the complete process of serialization and subsequent aggregation. This means that we not only comply with the EU Anti-Counterfeiting Directive, but can also serve countries where aggregation is mandatory.

For this purpose, we work together with a qualified service provider who converts your xml files into the xml format required by us and afterwards returns your files back to your database in your own xml format.

For this process it is irrelevant whether the folding boxes provided by you are flat or already filled.

We can also provide labels with serial numbers.

With the new T15 aggregation unit from Mettler-Toledo, Stegemann as a contract packer is now also able to map and offer the complete process of serialization and subsequent aggregation. This means that we not only comply with the EU Anti-Counterfeiting Directive, but can also serve countries where aggregation is mandatory.

Our semi-automatic coding machines are equipped with top-quality monitoring cameras.

The cameras check in line both the presence of the variable data and the quality of the 2D data matrix code.

Our semi-automatic coding machines are equipped with top-quality monitoring cameras.

The cameras check in line both the presence of the variable data and the quality of the 2D data matrix code.

Of course, we also provide your folding boxes with tamper-evident labels or carry out the adhesion of the tuck-in flaps so as to ensure that your product is a genuine article.

Furthermore, we attach your desired labels/leporellos to your items.

For this purpose, we use our various label dispensers and labelling machines. We also perform accurate manual adhesion in difficult places or for minimum batches.

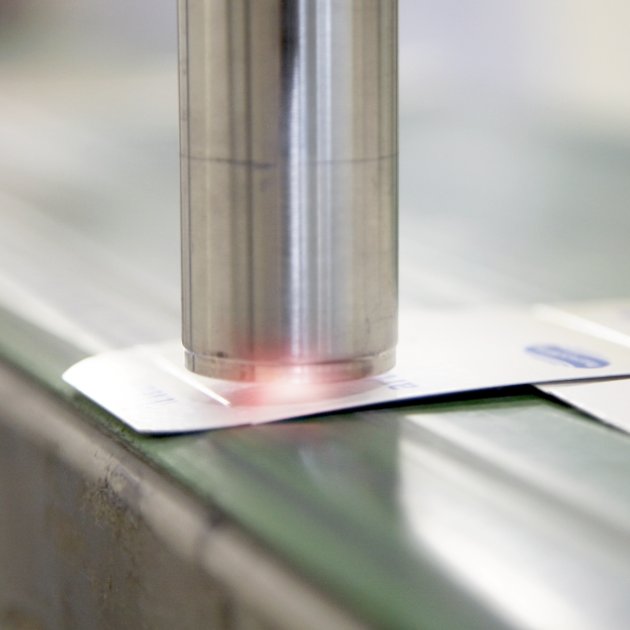

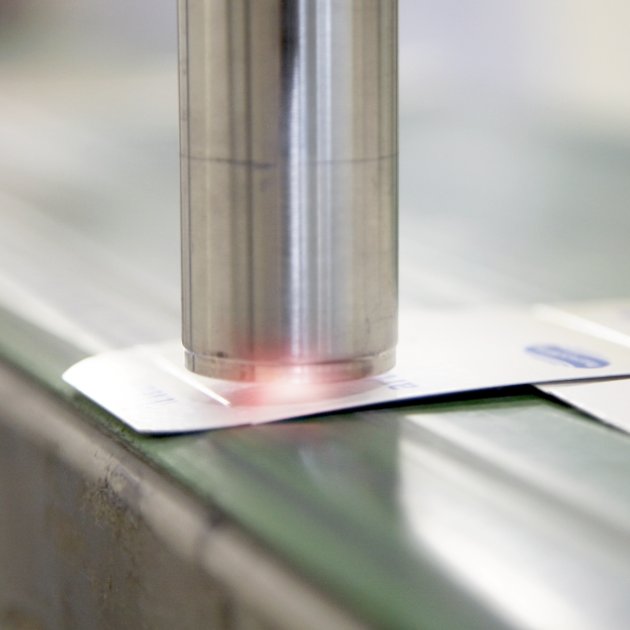

With this label printing dispensing system, labels can be printed, applied directly to the blisters and checked by a camera system.

Subsequently, the labeled products are then further packaged.

Of course, we also provide your folding boxes with tamper-evident labels or carry out the adhesion of the tuck-in flaps so as to ensure that your product is a genuine article.

Furthermore, we attach your desired labels/leporellos to your items.

For this purpose, we use our various label dispensers and labelling machines. We also perform accurate manual adhesion in difficult places or for minimum batches.

With this label printing dispensing system, labels can be printed, applied directly to the blisters and checked by a camera system.

Subsequently, the labeled products are then further packaged.